The oil extracted from the subterranean oil layer is accompanied by water and sediment, and inorganic salts such as NaCl, MgCl2, CaCl2, etc. are dissolved in the water.

The oil extracted from the subterranean oil layer is accompanied by water and sediment, and inorganic salts such as NaCl, MgCl2, CaCl2, etc. are dissolved in the water. The existence of these substances is very harmful to the processing process, so they must be removed by electric desalination. Since most of the inorganic salts are soluble in water, desalting and dehydration are carried out simultaneously. In order to remove the salt particles suspended in the crude oil, a certain amount of fresh water is injected into the crude oil (the injection amount is generally 5%), and a demulsifier is added at the same time, which is helpful for the breaking of the emulsified film in the emulsifier and the removal of inorganic salts. Removal: After fully mixing, under the action of the electric field, the tiny water droplets are coalesced into large water droplets, and the process of separating oil and water under the action of gravity is called electric desalting.

The fresh water must be exchanged with the electric desalination drainage to 80-90 ℃ and then used as the electric desalination water injection.

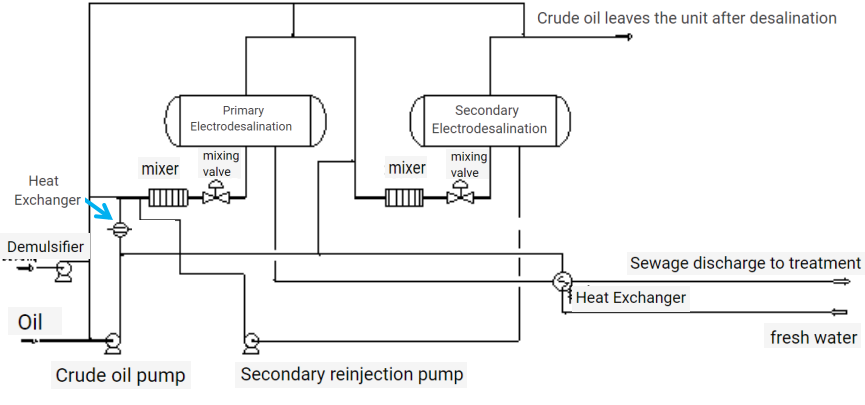

The injection points of water injection for electric desalination are set to 3, one injection point in front of the primary and secondary mixing systems, and a new injection point in front of the heat exchanger. The water injection volume is about 1% (if necessary). The mixed effect of the pipeline, so that the salt in the crude oil is dissolved in the water, and it acts together with the demulsifier, which is beneficial to the desalination of the crude oil.

The secondary electric desalination tank is injected with fresh water, and the secondary electric desalination drainage is used as the primary electric desalination water injection. Considering the actual operation situation, both primary and secondary lines need to have double lines that can be injected with fresh water, and secondary drainage also needs to have double lines to drain directly to the sewage pipeline outside the tank.

The two-stage electric desalination process is adopted, one tank is one stage, and the desalination process flow is shown in the following figure:

The company’s technology center is equipped with multiple (sets) simulation test devices such as electric desalting/dehydration simulation test platform, electrostatic coalescence electric dehydration test device, and sewage treatment experimental device, as well as complete inspection and testing instruments.

There are a number of projects with rich practical experience. technicians and R&D personnel. In the fields of heavy and inferior crude oil electric desalination/water treatment technology, industrial wastewater treatment technology and other fields, a number of inventions and new utility patents have been obtained, among which “a kind of crude oil desalination / water squirrel cage electrode” This patented technology replaced the United States for the first time in 2000. /Water technology, from now on realize the localization of electric dehydration.